- Location

- Alberta, Canada

- Offices

-

- Location

- Alberta, Canada

- Offices

Share

Centrifugal Gas Compressor

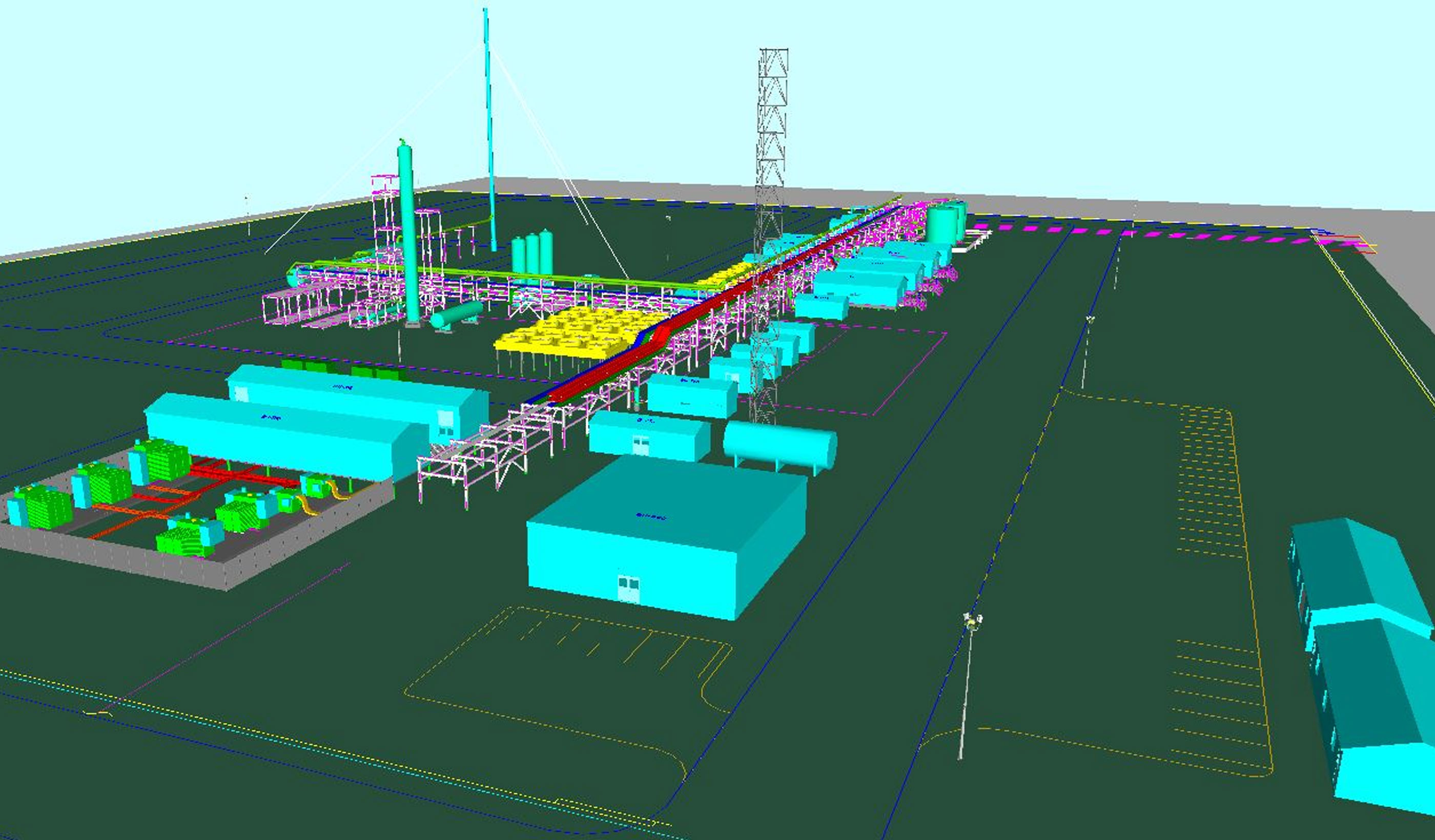

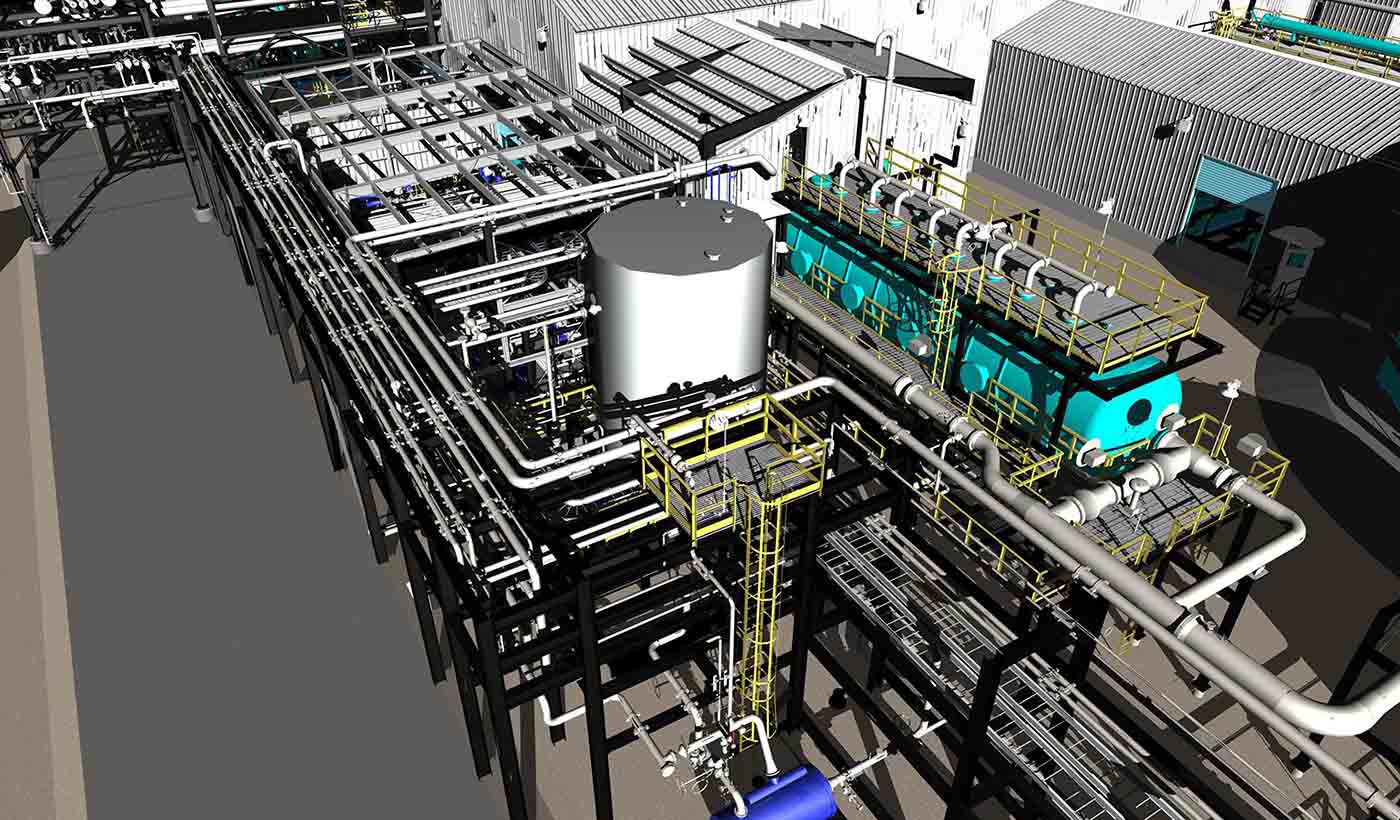

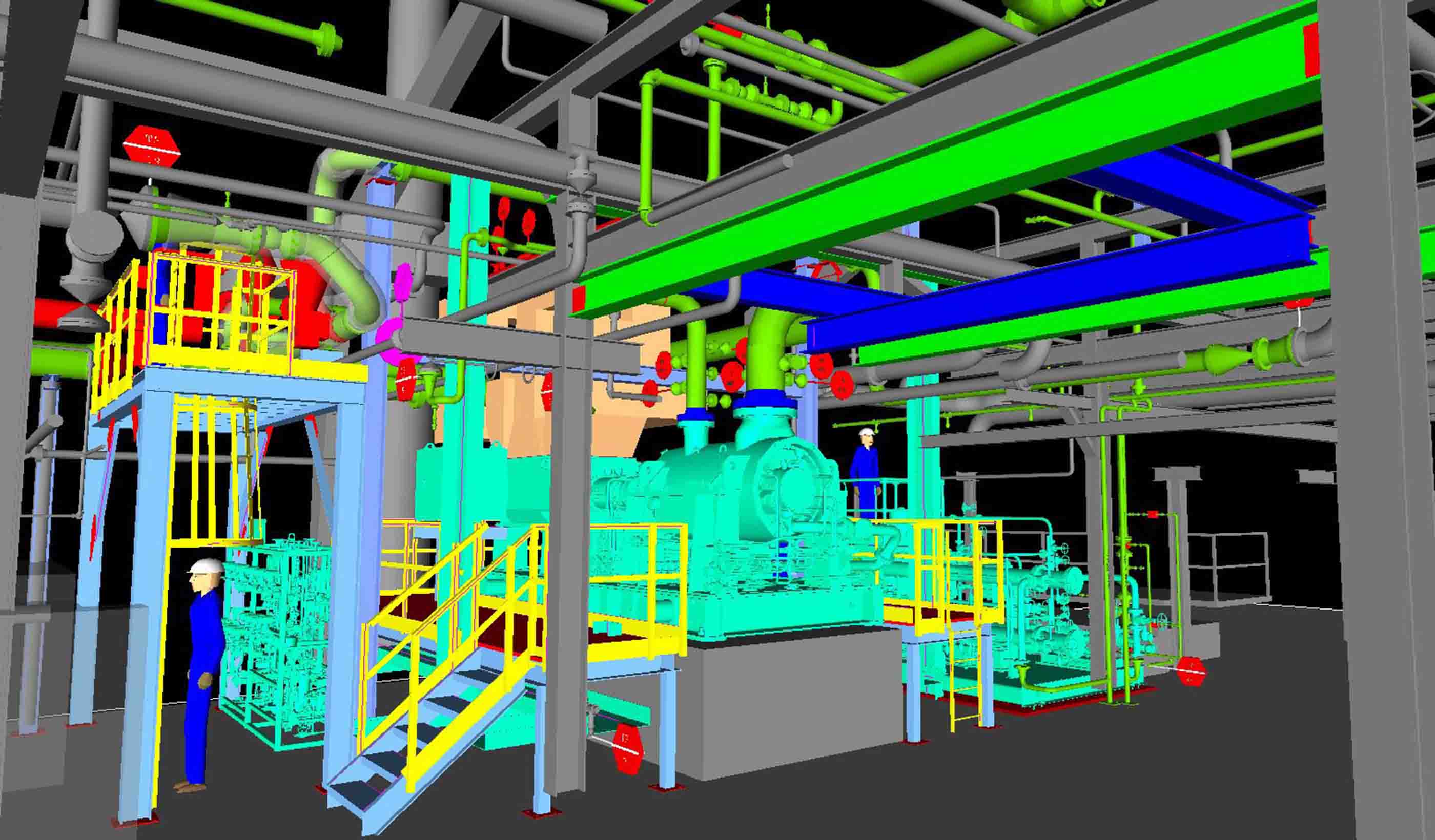

An operating sour gas plant needed a new centrifugal gas compressor—and the job came to us.

For this project, our role was to provide FEED and detailed engineering and procurement to support the installation of a new 2500 HP Elliott compressor c/w lube oil console skid, nitrogen generator package, and gas seal system. The project also required the installation of utility systems including a dry air system for the nitrogen package, an electric motor purge system with blower and ductwork, and a variable frequency drive in a self-contained building with HVAC.

With the congested and confined work area, we had to get creative. To allow compressor installation and keep the utility systems online, process and utility tie-ins to the existing facility were installed during a plant turn around.

With flexibility and inventiveness, our team tackled this project and met the complex needs of the client without delay or difficulty.

- Location

- Alberta, Canada

- Offices

-

- Location

- Alberta, Canada

- Offices

Share

Brian Schreuder, Director of Business Development, Energy & Resources

Listening and understanding your client’s goals and objectives is essential for meeting or exceeding their expectations.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.