At a Glance

-

180K

Square Feet

- Location

- Balzac, Alberta

- Offices

-

-

Client

-

-

Enterra Feed Corporation

-

- Location

- Balzac, Alberta

- Offices

- Client

-

- Enterra Feed Corporation

Share

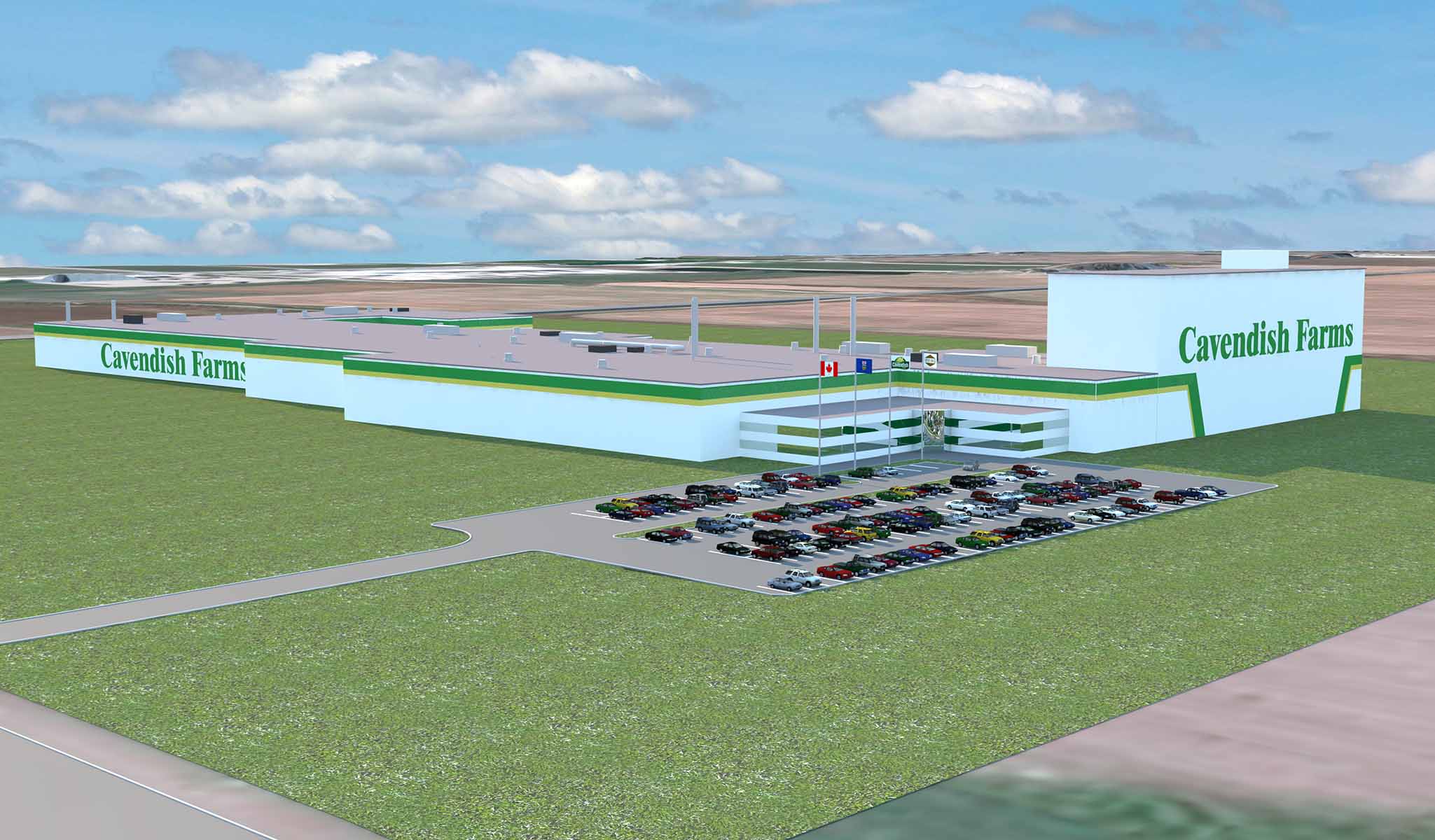

Enterra - Industrial Insect Protein Production Facility

Enterra, a company focused on delivering sustainable protein sources for pets, poultry, fish, and birds, wanted to construct a new industrial production facility and that would greatly improve their output. Our job? Scaling up and reconfiguring Enterra’s previous operations into an existing warehouse shell.

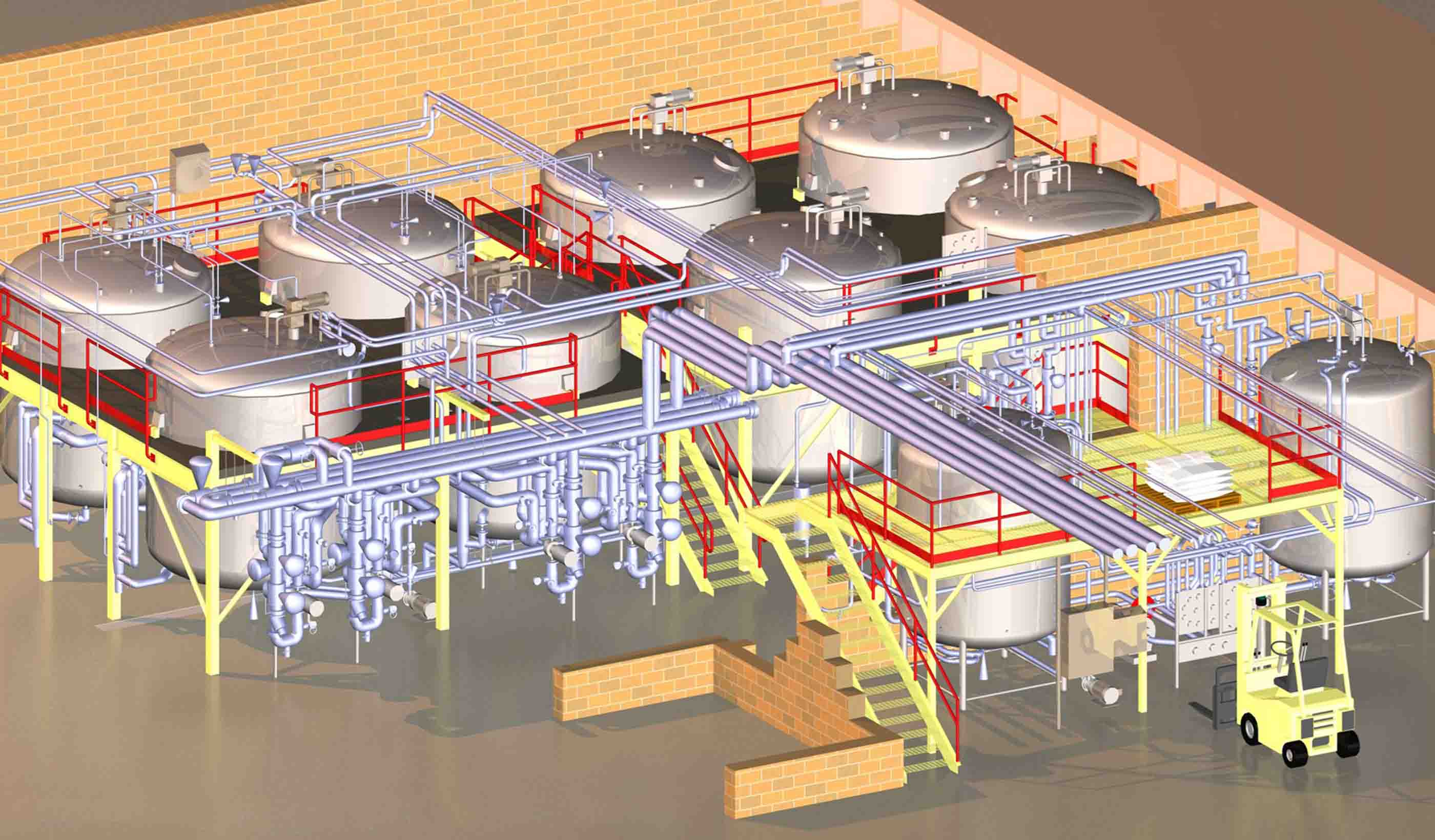

Working in collaboration with Enterra stakeholders, we developed the preliminary process layout, functional program, and concept plans that would increase production and efficiency. We contributed Class C costing to confirm budget compliance as well as process flow diagrams (PFD), process and instrumentation diagrams (P&ID), and dynamic models of the materials handling systems. With the dynamic model in place, we further refined the proposed processes.

The final design included dynamic modeling for dual over-head craning activities (900 movements per day), blast mitigation measures for classified areas, and compliance with security and sanitation code requirements for insect rearing. The final facility? Forty times larger than Enterra’s previous operations—a massive upgrade to their output capacity.

At a Glance

-

180K

Square Feet

- Location

- Balzac, Alberta

- Offices

-

-

Client

-

-

Enterra Feed Corporation

-

- Location

- Balzac, Alberta

- Offices

- Client

-

- Enterra Feed Corporation

Share

Alan Schnerch, Principal, Industrial Engineering Practice Lead

I work with our clients to ensure that process optimization and building design go hand-in-hand—as they should.

Myron Paryniuk, Principal, Manufacturing Lead

It doesn’t matter what industry you’re in—the ability to develop a dialogue and interface with clients sets you apart from the competition.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.